Meiwha CNC Pneumatic Hydraulic Vise

Boitsebiso ba Parameter ea Pneumatic Hydraulic Vise:

Boima ba sehlahisoa: 52-58 °

Lintho tse bonahalang: Nodular cast iron

Ho nepahala ha sehlahisoa:≤0.005

| Katse.No | Bophara ba mohlahare | Bophahamo ba mohlahare | Bophahamo | Bolelele | Max.Claping |

| MWP-5-165 | 130 | 55 | 165 | 525 | 0-150 |

| MWP-6-160 | 160 | 58 | 163 | 545 | 0-160 |

| MWP-6-250 | 160 | 58 | 163 | 635 | 0-250 |

| MWP-8-350 | 200 | 70 | 187 | 735 | 0-350 |

Melemo ea mantlha ea Pneumatic Hydraulic Vise:

Karolo ea 1.Peneumatic:Moea o hatelitsoeng (ka tloaelo 0.4 - 0.8 MPa) o kena ka valve ea solenoid ea vise.

2. Phetoho ea Hydraulic:Moea o hatelitsoeng o sututsa piston ea cylinder ea sebaka se seholo, e hokahaneng ka kotloloho le piston ea hydraulic piston ea sebaka se senyenyane. Ho ea ka molao-motheo oa Pascal (P₁ × A₁ = P₂ × A₂), tlas'a tšusumetso ea phapang ea sebaka seo, moea o tlaase o fetoha oli e phahameng ea khatello.

3. Ts'ebetso ea ho koala:Oli e hlahisoang ke khatello e phahameng e romelloa ho silindara e koalang ea vise, e tsamaisang mohlahare o sisinyehang oa vise ho sisinyeha, ka hona ho sebelisa matla a maholo ho koala sekhechana sa mosebetsi.

4. Ho boloka khatello le ho lokolla:Ho na le valve ea tsela e le 'ngoe ka hare ho vise, e ka bolokang khatello ea oli esita le ka mor'a hore phepelo ea moea e khaotsoe, ho netefatsa hore matla a ho koala ha a lahlehe. Ha ho hlokahala ho lokolloa, valve ea solenoid e khutlela morao, oli ea hydraulic e khutlela morao, 'me mohlahare o sisinyehang o khutla ka ketso ea selemo.

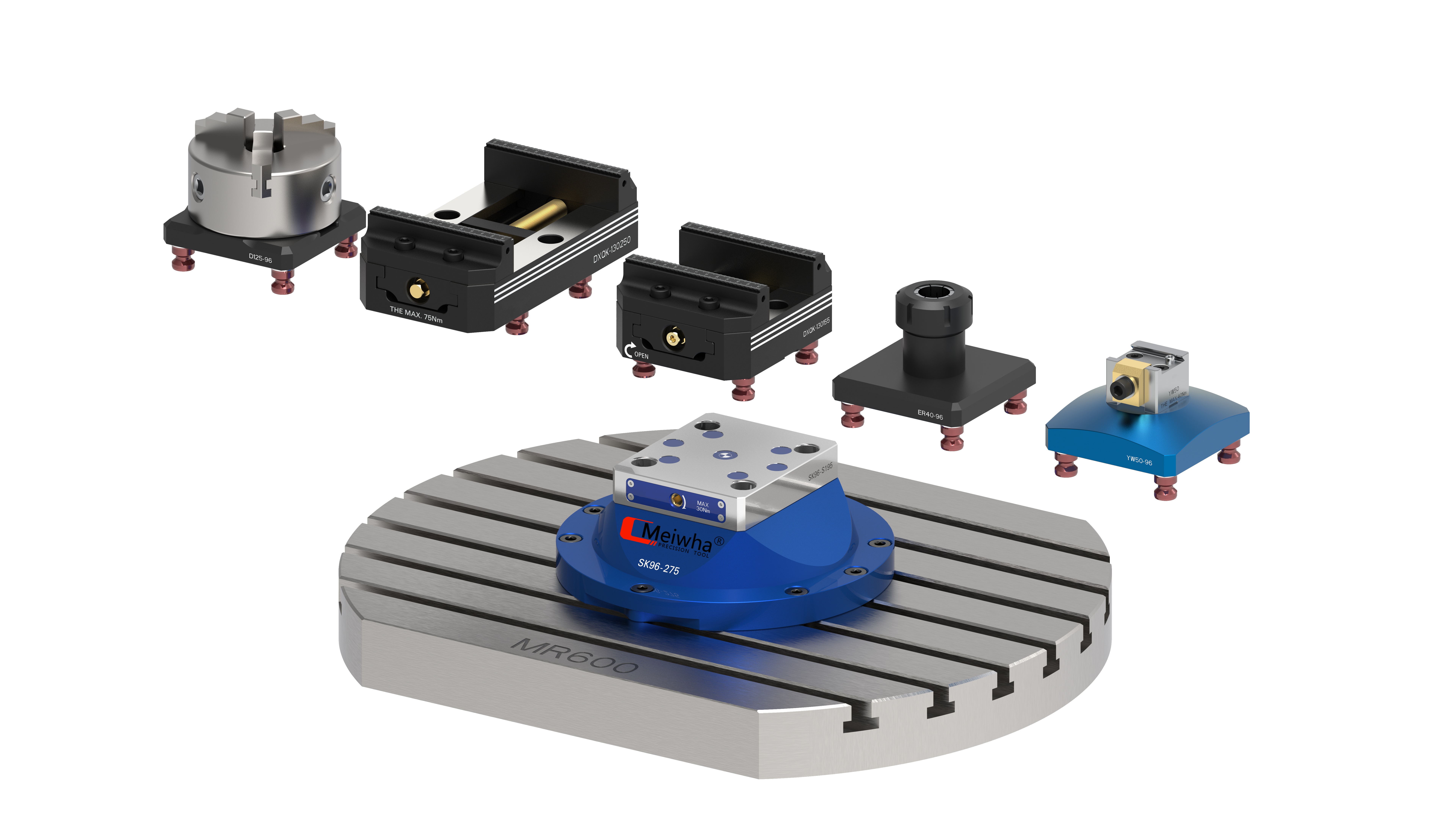

Letoto la Precision Vise

Meiwha Pneumatic Vise

Ho sebetsa ka mokhoa o tsitsitseng, ho koala ka potlako

Ha e khelosoe, e Nepahetse Clamping

Sebopeho sa phetisetso e hahelletsoeng ka ho kobeha holimo se netefatsa hore matla a sebelisoang nakong ea clamping a ea tlase. Ka hona, ha o tiisa sesebedisoa le ha mohlahare o sisinyehang o ntse o sisinyeha, o thibela mohlahare o kobehelang holimo, 'me mohlahare o siloa hantle le ho siloa.

Ho sireletsa sesebelisoa sa mochini le sesebelisoa sa mochini:

E na le valve e fokotsang khatello e feto-fetohang, e thusang ho lokisoa hantle ha khatello ea oli e tsoang 'me ka hona e lumella ho laola ka nepo matla a clamping. E qoba likotsi tsa ho senya lisebelisoa tsa mosebetsi tse nepahetseng ka lebaka la matla a mangata a tlamang kapa ho baka deformation ea li-workpieces tse tšesaane. Hona hape ke molemo o moholo oa eona ha o bapisoa le vise ea mochini feela.