Li-Drills tsa Indexable

Mesebetsi e mengata: Li-drill tse nang le indexable li khona ho cheka boholo ba mekoti, ho tloha ho tse nyenyane ho ea ho tse kholo tsa bophara, 'me li ka sebelisoa linthong tse fapa-fapaneng, ho akarelletsa le litšepe, polasetiki le metsoako.

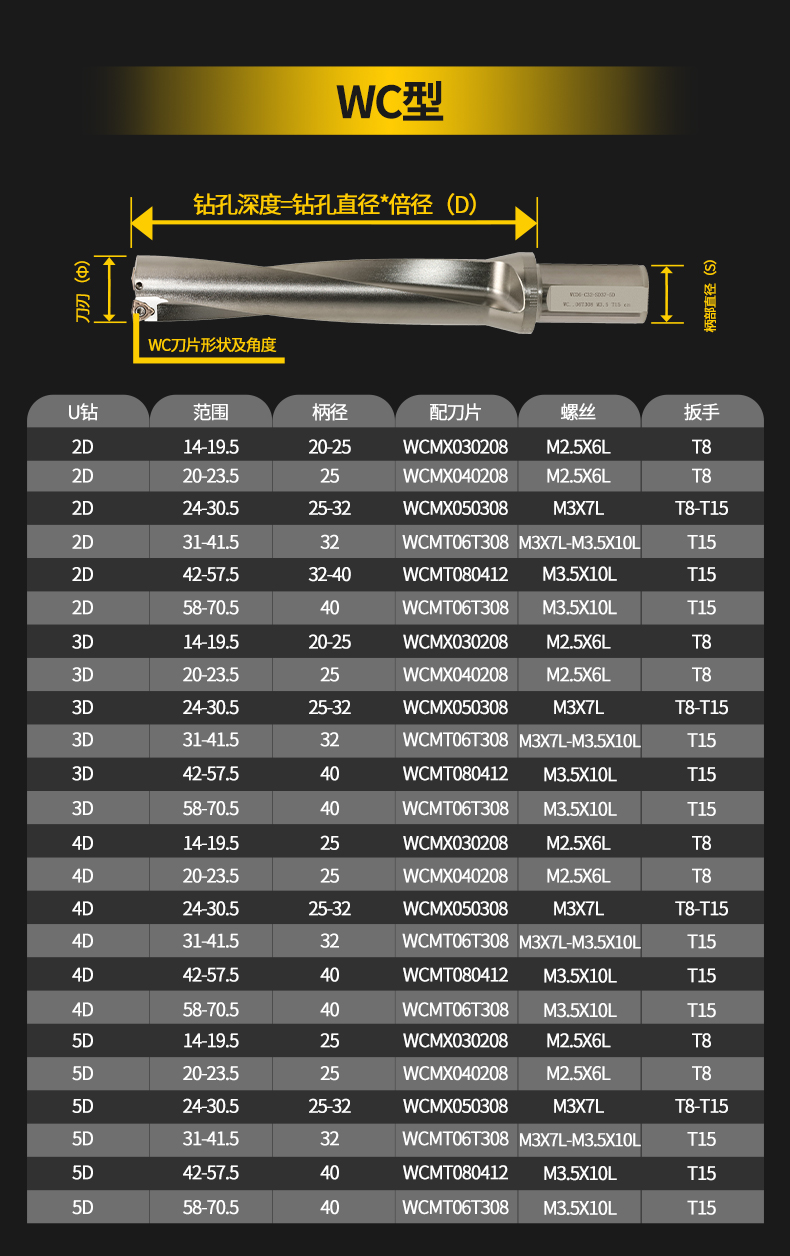

Moralo oa Modular: Li-drill tse lekantsoeng hangata li entsoe ka moaho oa modular, o lumellang basebelisi ho etsa sesebelisoa ho fihlela litlhoko tsa bona tse ikhethileng. Sena se ka kenyelletsa ho khetha mofuta oa shank, mokhoa oa ho fana ka pholileng, le bolelele ba 'mele oa ho phunya.

Ho nepahala ho phahameng: Li-drill tse nang le indexable li etselitsoe ho fana ka maemo a holimo a ho nepahala le ho nepahala, e leng se li etsang hore li tšoanelehe bakeng sa lits'ebetso tse hlokang mamello e tiileng le liphetho tse ntle.

Sistimi ea ho fana ka pholiso: Li-drill tse bonts'itsoeng hangata li entsoe ka sistimi ea phepelo e pholileng, e thusang ho lelefatsa bophelo basesebelisoa sa ho sehaka ho fokotsa mocheso le khohlano nakong ea tšebetso ea ho phunya.

Nako e fokotsehileng: Li-drill tse ka sebelisoang hangata li na le bophelo bo bolelele ba lisebelisoa ho feta li-drill tse tiileng tsa carbide, ho bolelang hore ho na le nako e fokolang ea ho fetola lisebelisoa le tlhokomelo. Sena se ka fella ka tlhahiso e ntlafetseng le ho fokotsa litšenyehelo ka kakaretso.

Melemo:

1. Lisebelisoa tsa ho cheka tse theko e phahameng ka katleho li fokotsa litšenyehelo tsa ho sebetsa

2. Sistimi e bohareng ea sekoti se pholileng e thusa ho thibela ho roala ha lehare le ho ntlafatsa bokhoni ba ho itšeha

3. The optimized chip holding groove e eketsa ho tiea ha lehare la 'mele hape e etsa hore ho ntšoa ha chip ho be bonolo.

4. E na le ts'ebetso ea anti chipping ka bobeli le ts'ebetso ea ho roala ea lehare

5. Etsa bonnete ba hore ts'ebetso e babatsehang ea ho itšeha le 'mele oa ho qetela oa lesoba, o loketseng ho sebetsa ka mekoti e mengata

6. Lehare le ntlafalitsoeng la lehare le etsa hore ho itšeha ho sebetse hantle, ho fokotsa mojaro oa mochini, le ho ntlafatsa bophelo ba lehare

7. Mamello e tsitsitseng ea ho cheka